Fan & Pad Green House

We, Alexa Farms are a foremost Construction Company that makes Fan & Pad Greenhouses. It is used to provide a controlled growing environment to grow special crops and plants. This greenhouse is provided with special-purpose fans to draw air into the greenhouse through high-efficiency cooling pads made from high surface area ribbons of cellulose fibre. Humidity is controlled by an elaborate system of foggers. Fertigation is implemented by an efficient drip-irrigation system.This type of greenhouse is ideal for growing nursery plants. Plants grown for nursery propagation have to be provided with a very specific environment. Nursery plants are very valuable and need extreme care during the early stages of their development.This type of greenhouse is used in hydroponics system, i.e. Soil less cultivation system which enables us to grow the exotic vegetables such as Kale, Lettuce, Broccoli,Parsley, Zucchini, Peppers , Cherry Tomato ,Herbs like Basil, Oregano,Thyme, Ginger, Turmeric, fruits like Strawberries, Blueberries, Raspberry etc. in off season. Typically, exotic plants and crops meant for the export market or as import-substitutes are grown in such greenhouses. The temperature and humidity can be controlled to provide the exact growing environment required for plants that grow in temperate regions.Cooling Pads

Evaporative Cooling

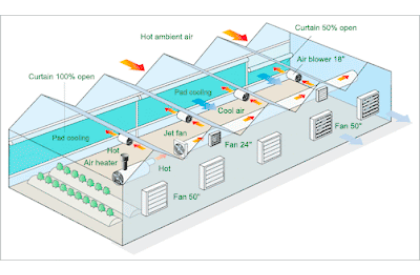

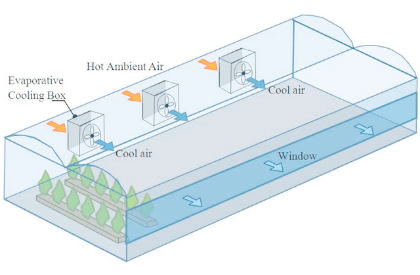

Evaporative cooling is a tool that can be used to reduce greenhouse temperatures. A “fan and pad” system uses exhaust fans to pull air through evaporative cooling pads. This technique utilizes the cooling effect produced when water evaporates and cools the air as it is pulled through the pad.

Cooling pads cool by creating large amounts of surface area that are exposed to air being drawn into the greenhouse by exhaust fans. This large surface area allows for quick evaporation. Common pad materials include cellulosic materials or aspen fiber pads. Cellulosic pad materials are the preferred choice by most growers as they last longer than aspen pads.

PAD SYSTEM – The reduction in air temperature only occurs around the exhaust side of the cooling pad. Even in a well-designed greenhouse, air can easily pick up over 8 to 9 °F as it passes through the greenhouse. Cooling pads are able to achieve targeted temprature efficiency as per crops. For a freestanding 30 x 96 ft. greenhouse, cooling pad equipment cost can be anywhere from $1800-$2000. Depending on your situation, the cooling capacity of a fan and pad system may or may not be significant enough to justify that level of investment.

Fan and pad systems need to be sized appropriately to achieve the maximum cooling efficiency. When a fan and pad system cannot be justified, in some situations passive ventilation with open sided greenhouses may provide adequate cooling for a given crop without using any energy. In the case where biosecurity or insect exclusion is a priority, a closed greenhouse with a fan and pad system may be necessary. Greenhouse lettuce growers in Baldwin County have had great success with cooling pads in combination with reflective shade cloths. Floriculture growers throughout Alabama have also had great success with passively ventilated greenhouses.

Cooling pads require regular maintenance to insure they remain efficient. Algae and mineral build up can reduce air movement and lower efficiency. Consult with the cooling pad manufacturer before applying any chemicals, as some can reduce the life expectancy of pad materials.

Structure Specifications

Evaporative cooling is a tool that can be used to reduce greenhouse temperatures. A “fan and pad” system uses exhaust fans to pull air through evaporative cooling pads. This technique utilizes the cooling effect produced when water evaporates and cools the air as it is pulled through the pad.

Cooling pads cool by creating large amounts of surface area that are exposed to air being drawn into the greenhouse by exhaust fans. This large surface area allows for quick evaporation. Common pad materials include cellulosic materials or aspen fiber pads. Cellulosic pad materials are the preferred choice by most growers as they last longer than aspen pads.

| PARTICULAR | SPECIFICATIONS |

|---|---|

| Product | Fan and pad Greenhouse |

| Bay Size | 8-9 Meter (Span) x 4-5 Meter (Bay) |

| Top Height | 5.5-6.5 Meter |

| Gutter Height | 3-5 meter from Floor Area |

| Gutter Slop | 2% or as per requirement |

| Gutter Frame | Industrial Press Gutter made from GI Coil of 500mm Width |

| Gutter Clamp | Made From Hot Dip Galvanized Sheet of 2.5mm Thickness |

| Hockey | 2.5 Meter Two side. |

| Columns Pipe | 76 mm OD |

| Trusses / Bottom Pipe | 60 mm OD |

| Top Arches Pipe | 48 mm OD |

| Purlins Pipe | Top Purlin : 42 mm OD; Other Purlin : 33/27 mm OD |

| Foundation Pipe | 60 mm OD & 1.2 Meter Length |

| Fixing of cladding materials | All ends/joints of plastic film need to be fixed with two way Aluminum profiles |

| Cladding material | UV stabilized 200 micron, White Diffused 50% PE film conforming to standards having properties like Anti dust, Anti-drip, Anti-fog, IR thermic, light diffusion. |

| Cladding material | UV stabilized Mono * Mono Shade Net of 50% shade factor with manual operated mechanism. |

| Spring Insert | Zigzag high carbon steel spring action wire of 2.5 mm diameter |

| Apron | Two Side Laminated Apron for prevention of animal entering into greenhouse. |

| Shade Net | UV stabilized Shade Net of 50% shade factor with manual operated mechanism. |

| Gutter Funnel With Drainage Pipe | We have provide water harvesting system with gutter funnel with flexible pipe. |

| Fasteners | High Tensile Strength & Hot Dip Galvanized (120 GSM) |

| Entrance Door | Hinge Door made from Aluminum Frame & Polycarbonate Sheet |

| Exhaust Fan System | As Per Requirement of Temprature and Humidity |

| Cooling pad System | As Per Requirement of Temprature and Humidity |

merhaba,

fan ped sisteminde sera içi soğutulurken bağıl nem miktarı ne olur,artar mı azalır mı

I enjoyed reading this article. Thanks for sharing your insights.

Give quotation